Introduction of Welded Stainless Steel Tube for Pressure Purposes

EN-10217 specifies the technical delivery conditions in two test categories for stainless steel welded round tubes which are intended for pressure and corrosion resisting purposes at room temperature, at low temperatures or at elevated temperatures.

This standard is applicable to tubes with outside diameters mainly within the range of 10 mm and 508 mm.

For more product information, please refer to our catalog.

Products made of Austenitic series stainless steel with optional grades in MT-304, MT-304L or MT-316L are both durable and verstaile.

EN-10217 tubes are commonly utlized in pressure or corrosiion resisting equipment.

The tubes shall be manufactured from hot or cold rolled plate, sheet or strip in accordance with EN 10028-7.

EN10217-7 tubes can have different surface finishes that will suit different needs.

EN 10217-7 tubes comply with mandatory requirement of EU Directive 2014/68/EU.

Inspection document 3.1 can be provided if requested by customers.

Welding is performed only by qualified personnel.

YC INOX CO., LTD is a global leading stainless steel pipe & tube manufacturer.

Our professional manufacturing and engineering teams offer products with excellent and consistent quality to our clients all around world.

Our prompt after-sales services can always be relied on by our customers.

Our punctual delivery time makes stock control easy for our customers.

We offer product with tolerance complies with the norm (Specific tolerance requirement is possible. Please contact our sales specialists).

Specific mechanical tests are negotiable between seller and buyer.

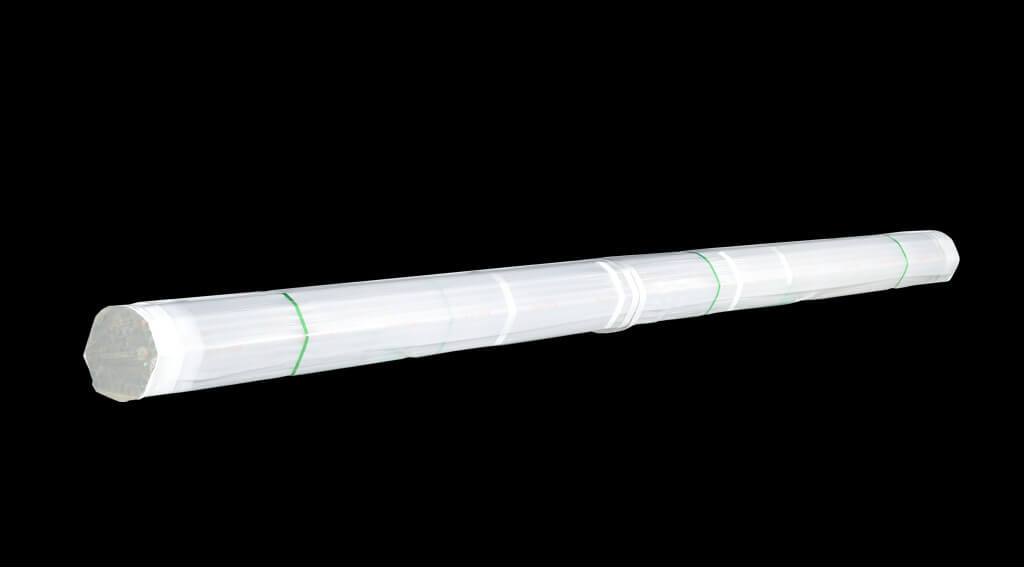

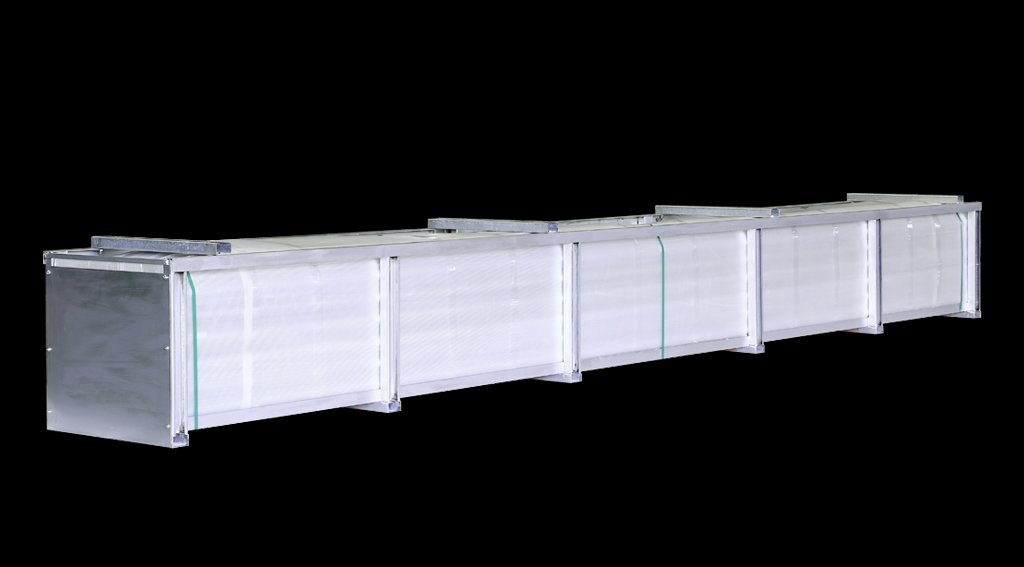

Bundle packing or steel crate packing is available in accordance with clients' preference.

Optional supplementary requirements are negotiatable.

YC INOX, your best choice of stainless steel.

EN 10217-7

| Outside Diameter (mm) | Thickness (mm) | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.0 | 1.2 | 1.5 | 1.6 | 2.0 | 2.3 |

2.5 2.6 |

3.0 | 3.2 |

3.5 3.6 |

4.0 | 5.0 | 5.5 | 6.0 | 6.5 | 7.1 | 8.0 | 9.0 | 10.0 | |

|

10 |

☐ | ☐ | |||||||||||||||||

| 12 |  |

|

|

|

|||||||||||||||

| 15 | ☐ | ☐ | ☐ | ☐ | ☐ | ||||||||||||||

| 16 |  |

|

|

|

|

||||||||||||||

| 17.2 | Δ | Δ | Δ | Δ | Δ | ||||||||||||||

| 18 / 20 |  |

|

|

|

|

||||||||||||||

| 21.3 |  |

|

|

|

|

|

|

||||||||||||

| 22 |  |

|

|

|

|

||||||||||||||

| 25 |  |

|

|

|

|

|

|

|

|||||||||||

| 26.9 |  |

|

|

|

|

|

|

||||||||||||

| 28 / 30 |  |

|

|

|

|

|

|

|

|||||||||||

| 31.8 / 32 |  |

|

|

|

|

|

|

|

|||||||||||

| 33.7 |  |

|

|

|

|

|

|

|

|

|

|||||||||

| 35 / 38 / 38.1 |  |

|

|

|

|

|

|

|

|||||||||||

| 40 |  |

|

|

|

|

|

|

|

|||||||||||

| 42.4 |  |

|

|

|

|

|

|

|

|

|

|

||||||||

| 44.5 |  |

|

|

|

|

|

|

|

|||||||||||

| 48.3 |  |

|

|

|

|

|

|

|

|

|

|

||||||||

| 50.8 / 51 |  |

|

|

|

|

|

|

||||||||||||

| 54 / 57 |  |

|

|

|

|

|

|

||||||||||||

| 60.3 |  |

|

|

|

|

|

|

|

|

|

|

||||||||

| 63.5 |  |

|

|

|

|

|

|

||||||||||||

| 70 |  |

|

|

|

|

|

|

||||||||||||

| 76.1 |  |

|

|

|

|

|

|

|

|

|

|

||||||||

| 88.9 / 101.6 |  |

|

|

|

|

|

|

|

|

|

|

|

|||||||

| 114.3 | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ |  |

|

|

|

|

|

|||||||

| 139.7 | Δ | Δ |  |

|

|

|

|

|

|||||||||||

| 168.3 | Δ |  |

|

|

|

|

|

|

|

||||||||||

| 219.1 |  |

|

|

|

|

|

|

|

|

|

|||||||||

| 273 | |||||||||||||||||||

| 323.9 - 457 | |||||||||||||||||||

| 508 | |||||||||||||||||||

| Remark |

(1)Orange Mark:Non-annealed Spec. (2)Finish:( (3)CR Material:Thickness 1.0~3.0mm (4)HR Material:Thickness 2.0~10.0mm (5)Outside Diameter ≦ 114.3mm,Also available by ASTM A554 |

||||||||||||||||||

| Outside Diameter | Thickness | Length | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

D ≦ 168.3mm |

D3 ± 0.75 % or ± 0.3mm whichever is the greater |

T3 ± 10% or ± 0.2mm |

|

|||||||||

| D > 168.3mm | D2 ± 1.0 % | |||||||||||

Welded Circular Austenitic Stainless Steel Tubes

Welded Circular Austenitic Stainless Steel Tubes