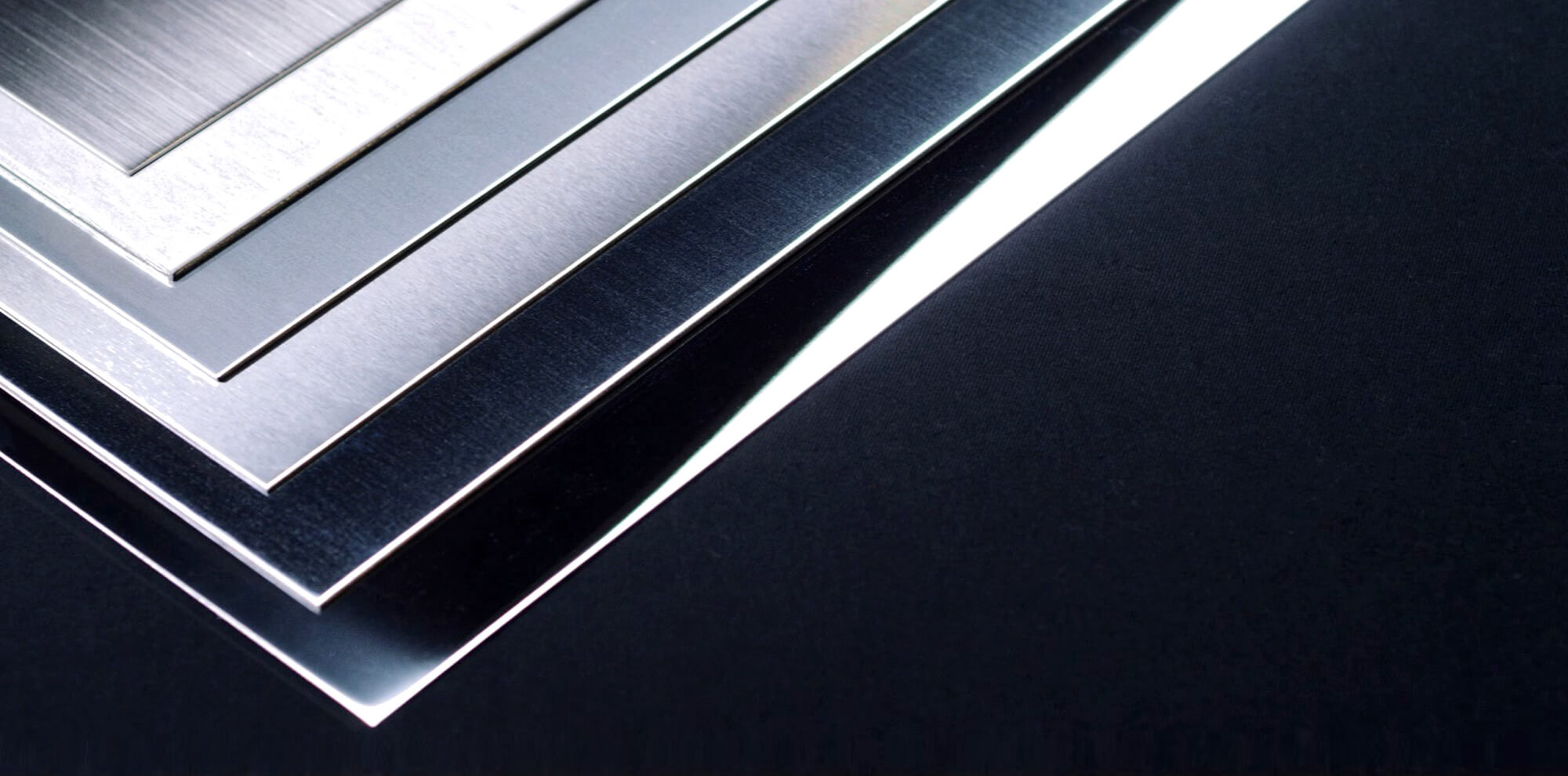

Introduction of Stainless Steel Sheets and Plates

YC INOX has been a key producer in the stainless steel industry for decades. We have made a name for ourselves as an excellent stainless steel sheet supplier in the world.

We offer both hot rolled and cold rolled stainless steel products which conform with the following international standards: ASTM A240/A240M, A480/A480M, JIS G4304/G4305, and EN 10028-7/10088-2.

Stainless steel sheets are versatile for many applications. These products are widely utilized as components of infrastructure, construction, bicycle, medical, home appliance, and kitchen implements.

The highly customizable nature of YC INOX’s stainless steel materials is highly praised by our customers. Customers can choose various material grades on the basis of their process requirements.

YC INOX supplies a wide range of thicknessese from 0.4 mm to 6.0 mm for cold rolled stainless steel sheets and 2.0 mm to 50.0 mm for hot rolled stainless steel sheets.

Available standard widths are 914/1000/1219/1250/1500/1524 mm. Other special sizes of sheets and plates may also be made according to customer's specification.

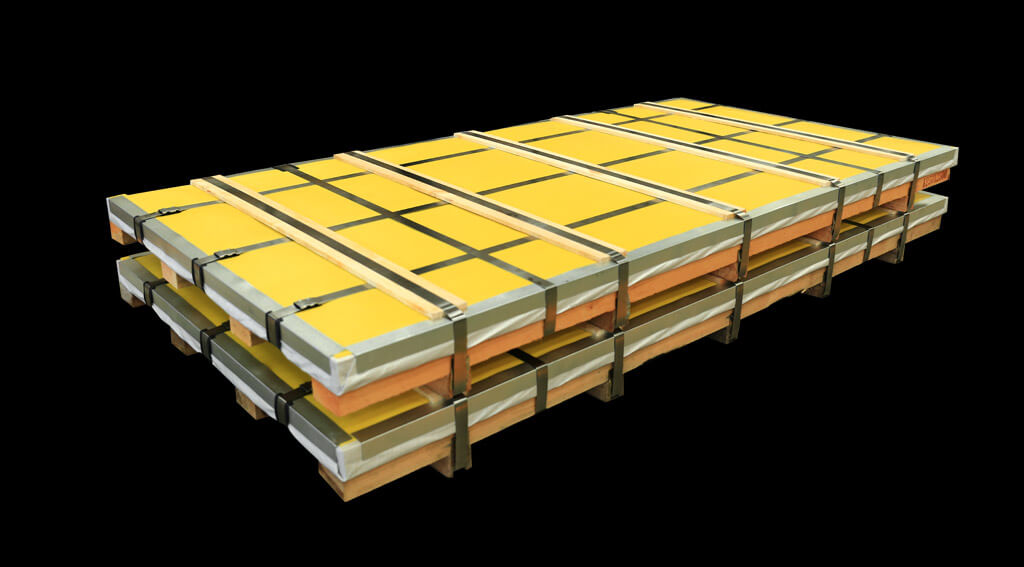

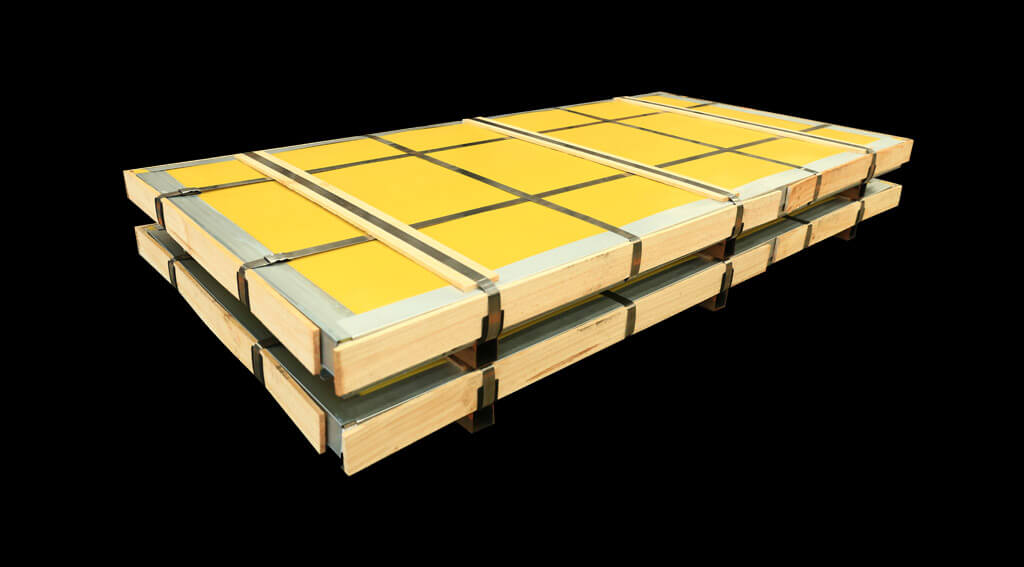

YC INOX is committed to provide suitable and reliable packaging for our customers. Customers may select the appropriate packaging for their shipment requirements according to their budget and

delivering plans. You can find more images of our products further down this page.

YC INOX CO., LTD is a global leading stainless steel pipe & tube manufacturer.

Our professional manufacturing and engineering teams offer products with excellent and consistent quality to our clients all around world.

Our prompt after-sales services can always be relied on by our customers.

Our punctual delivery time makes stock control easy for our customers.

We offer product with tolerance complies with the norm (Specific tolerance requirement is possible. Please contact our sales specialists).

Specific mechanical tests are negotiable between seller and buyer.

Bundle packing or steel crate packing is available in accordance with clients' preference.

Optional supplementary requirements are negotiatable.

YC INOX, your best choice of stainless steel.

ASTM A240/A240M, A480/A480M, JIS G4304/G4305, EN 10028-7/10088-2

| Product Type | Finish | Grade | Thickness (mm) | Width (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Main Size | Other Size | Application | |||||||||||

| 750 | 914 | 1000 | 1219 | 1250 | 1500 | 1524 | 2000 | ||||||

| Sheet & Plate | NO.1 | 304/L, 316L | 2.0 ≦ t<5.0 |  |

|

|

|

|

Upon Request | Petro-chemical industry, Tanks. | |||

| 5.0 ≦ t ≦ 12.7 |  |

|

|

|

|

|

|||||||

| 12.7<t ≦ 30.0 |  |

|

|

|

|||||||||

| t>30.0 | Upon Request | ||||||||||||

| 430 | 2.0 ≦ t ≦ 6.0 |  |

|

|

|

|

|||||||

| 409, 439 | 3.0 ≦ t ≦ 6.0 |  |

|

|

|

|

|||||||

| 2B | 304/L | 3.5 ≦ t ≦ 5.0 |  |

|

|

|

|

||||||

| 316L | 3.5 ≦ t ≦ 4.0 |  |

|

|

|

|

|||||||

| 304/L, 316L | 4.76 ≦ t ≦ 6.0 |  |

|

||||||||||

| 2B NO.4 NO.5 HL SB |

304/L | 0.4 ≦ t ≦ 3.0 |  |

|

|

|

|

|

|

(1)Size Range : 71~1524mm (2)71~800mm Max. Thickness:2.0mm |

Medical equipment, Food industry, Construction material, Kitchen utensils, BBQ grill. | ||

| 316L, 430 | 0.5 ≦ t ≦ 3.0 |  |

|

|

|

|

|

|

|||||

| 409 | 0.5 ≦ t ≦ 3.0 |  |

|

|

|

|

|

||||||

| 439 | 0.4 ≦ t ≦ 1.5 |  |

|

|

|

|

|

||||||

| 1.5<t ≦ 2.5 |  |

|

|

|

|||||||||

| BA | 304/L, 316L 430 |

0.4 ≦ t ≦ 2.0 |  |

|

|

|

|||||||

| NO.8 | 304/L, 316L | 0.6 ≦ t ≦ 2.0 |  |

|

Construction material | ||||||||

| Remark |

Feature 1.Oil base wet polished 2.Both-sides polished available 3.PE Coating normal / laser film 4.Line-marking 5.Package weight Sheet:1.25~2.2 mts Plate:2.0~4.0 mts |

||||||||||||

|

Standard & Grade |

Chemical Composition (%) |

Others |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

Mo |

N |

|||

|

ASTM A240 |

304 | ≦0.080 | ≦0.75 | ≦2.00 | ≦0.045 | ≦0.030 | 8.0~11.0 | 18.0~20.0 | - | ≦0.10 | |

| 304L | ≦0.030 | ≦0.75 | ≦2.00 | ≦0.045 | ≦0.030 | 8.0~12.0 | 18.0~20.0 | - | ≦0.10 | ||

|

316 |

≦0.080 | ≦0.75 | ≦2.00 | ≦0.045 | ≦0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | ≦0.10 | ||

| 316L | ≦0.030 | ≦0.75 | ≦2.00 | ≦0.045 | ≦0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | ≦0.10 | ||

| 321 | ≦0.080 | ≦0.75 | ≦2.00 | ≦0.045 | ≦0.030 | 9.0~12.0 | 17.0~19.0 | - | ≦0.10 |

Ti:0.70max. 5(C+N)min. |

|

| 409 | ≦0.030 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.020 | ≦0.50 | 10.5~11.7 | - | ≦0.030 |

Ti:0.50max. 6(C+N)min. Cb:0.17max. |

|

| 439 | ≦0.030 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | ≦0.50 | 17.0~19.0 | - | ≦0.030 |

Ti:1.10max. 0.20 + 4(C+N)min. Al:0.15max. |

|

| 430 | ≦0.120 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.030 | ≦0.75 | 16.0~18.0 | - | - | ||

|

JIS G4304 G4305 |

SUS304 | ≦0.080 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 8.0~10.5 | 18.0~20.0 | - | - | |

| SUS304L | ≦0.030 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 9.0~13.0 | 18.0~20.0 | - | - | ||

| SUS316 | ≦0.080 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | - | ||

| SUS316L | ≦0.030 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 12.0~15.0 | 16.0~18.0 | 2.0~3.0 | - | ||

| SUS321 | ≦0.080 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.030 | 9.0~13.0 | 17.0~19.0 | - | - | Ti:5C min. | |

| SUS430 | ≦0.120 | ≦0.75 | ≦1.00 | ≦0.040 | ≦0.030 | ≦0.60 | 16.0~18.0 | - | - | ||

|

EN 10028-7 10088-2 |

1.4301 | ≦0.070 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.015 | 8.0~10.5 | 17.5~19.5 | - | ≦0.10 | |

| 1.4307 | ≦0.030 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.015 | 8.0~10.5 | 17.5~19.5 | - | ≦0.10 | ||

| 1.4401 | ≦0.070 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.015 | 10.0~13.0 | 16.5~18.5 | 2.0~2.5 | ≦0.10 | ||

| 1.4404 | ≦0.030 | ≦1.00 | ≦2.00 | ≦0.045 | ≦0.015 | 10.0~13.0 | 16.5~18.5 | 2.0~2.5 | ≦0.10 | ||

|

EN 1088-2 |

1.4016 | ≦0.080 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.015 | - | 16.0~18.0 | - | - | |

| 1.4509 | ≦0.030 | ≦1.00 | ≦1.00 | ≦0.040 | ≦0.015 | - | 17.5~18.5 | - | - |

Ti:0.1~0.6 Nb:0.3+3*C~1.0 |

|

Stainless Steel HR Tolerance (by cutting method)

Unit: mm

| Standard | Item | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tolerance in Width | Tolerance on Length | Maximum Value of Flatness of Plate | |||||||||

| ASTM A480/A480M | T<5 | T≧5 T≦10 |

T>10 | L<3000 | +6.35/-0 | T<5 | T≧5 | ||||

| W<900 | 12.7 | 23 | |||||||||

| W>1200 | +1.59/-0 | +3.97/-0 | +6/-0 | L≧3000 L≦6000 |

+12.7/-0 | W≧900 W<1500 |

19 | 23 | |||

| W≧1200 | +6/-0 | +9/-0 | +11.1/-.0 | W≧1500 | 25.4 | 30 | |||||

| CNS 8497 JIS G4304 |

L≦3500 | L>3500 L≦6000 |

L>6000 | L≦3500 | L>3500 L≦6000 |

L>6000 | W≦1000 | L≦2000 | 15 | ||

| L>2000 | 20 | ||||||||||

| T<10 | +5/-0 | +15/-0 | +20/-0 | T<10 | +10/-0 | +15/-0 | +30/-0 | W>1000 W≦1600 |

20 | ||

| T≧10 T≦20 |

+10/-0 | +20/-0 | +20/-0 | T≧10 T≦20 |

+15/-0 | +20/-0 | +35/-0 | ||||

Stainless Steel CR Sheet Tolerance (by cutting method)

Unit: mm

| Standard | Item | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tolerance on Width | Tolerance on Length | Maximum Value of Flatness of Plate | |||||||||

| ASTM A480/A480M | T≦1.5 | T>1.5 T≦2.5 |

T>2.5 T≦3.5 |

L≦2000 | +4.8/-0 | W<1500 | W≧1500 | ||||

| W>600 W<1200 |

+1.5/-0 | +1.6/-0 | +1.6/-0 | L>2000 | +0.0025xL/-0 | 10 | 12 | ||||

| W≧1200 W≦2100 |

+2/-0 | +2.5/-0 | +3/-0 | ||||||||

| CNS 8499 JIS G4305 |

L≦3500 | L>3500 L≦6000 |

L>6000 | L≦3500 | L>3500 L≦6000 |

L>6000 | W≦1000 | L≦2000 | 15 | ||

| L>2000 | 20 | ||||||||||

| T<10 | +5/-0 | +15/-0 | +20/-0 | T<10 | +10/-0 | +15/-0 | +30/-0 | W>1000 | 20 | ||

| T≧10 T≦25 |

+10/-0 | +20/-0 | +20/-0 | T≧10 T≦25 |

+15/-0 | +20/-0 | +35/-0 | ||||

HR/CR Sheet/Plate

HR/CR Sheet/Plate

HR/CR Sheet/Plate

HR/CR Sheet/Plate

HR/CR Sheet/Plate