Introduction of Stainless Steel Welded Pipe

JIS G3459 and CNS6331 Stainless Steel Pipes Standard specifies Stainless Steel Pipes used for piping for corrosion resistance, low temperature service, elevated temperature service, fire-fighting services etc.

These pipes are widely used in various application industry like oil & gas, paper, breweries, cement, sugar, oil mills, mining, shipbuilding, steel plants, and etc.

JIS G3459 pipes have outside diameters mainly within the range between 13.8 mm (nominal diameter 8A or 1/4B) and 660.4 mm (nominal diameter 650A or 26B).

The pipes of JIS G3459 are available with grade in SUS304TP, 304LTP, SUS316TP, 316LTP, whereas the pipes of CNS 6331 are available with grades in 304/A304L, 316/A316L.

All pipes are available in different sizes and thicknesses. Please refer to our catalog for more information.

YC INOX CO., LTD is a global leading stainless steel pipe & tube manufacturer.

Our professional manufacturing and engineering teams offer products with excellent and consistent quality to our clients all around world.

Our prompt after-sales services can always be relied on by our customers.

Our punctual delivery time makes stock control easy for our customers.

We offer product with tolerance complies with the norm (Specific tolerance requirement is possible. Please contact our sales specialists).

Specific mechanical tests are negotiable between seller and buyer.

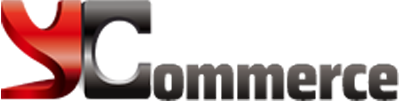

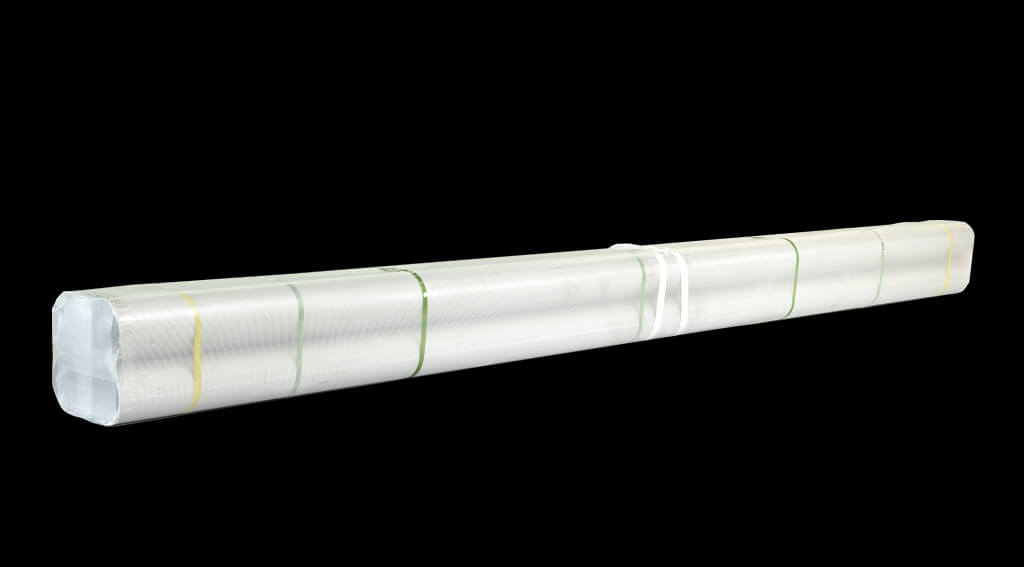

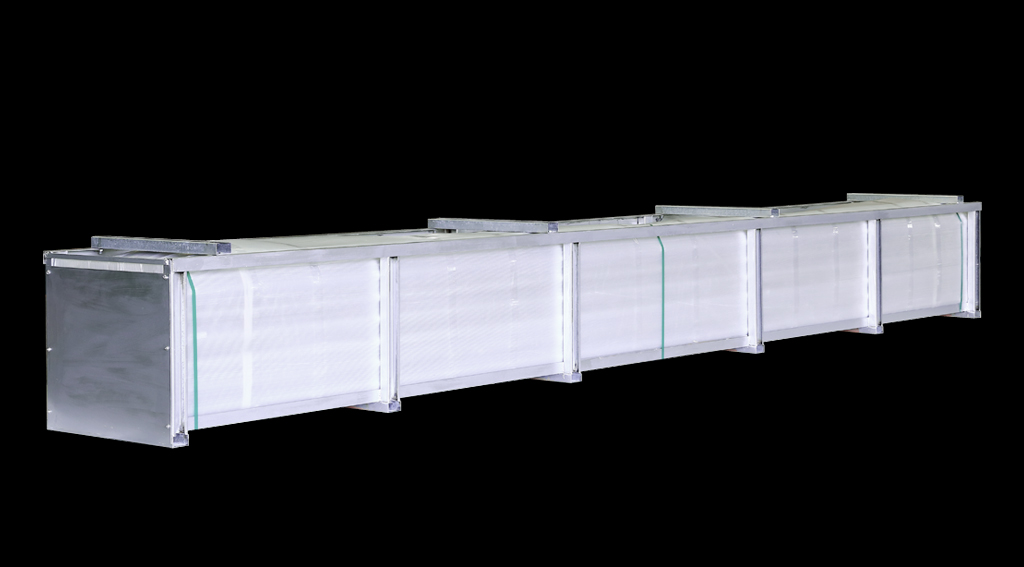

Bundle packing or steel crate packing is available in accordance with clients' preference.

Optional supplementary requirements are negotiatable.

YC INOX, your best choice of stainless steel.

JIS G3459, CNS 6331

| Nominal Diameter | Outside Diameter (mm) | Nominal Wall Thickness (mm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| JIS G3459 , CNS 6331 | JIS G3468 , CNS 13517 |

Other Common Thickness |

|||||||||

| A | B | SCH 5S | SCH 10S | SCH 20S | SCH 40 | SCH 5S | SCH 10S | SCH 20S | SCH 40 | ||

| 8 | 1/4 | 13.8 | 1.2 | 1.65 | 2.0 | 2.2 | - | - | - | - | - |

| 10 | 3/8 | 17.3 | 1.2 | 1.65 | 2.0 | 2.3 | - | - | - | - | 1.5/2.5 |

| - | - | 20.4* | - | - | - | - | - | - | - | - | 2.0/2.5 |

| 15 | 1/2 | 21.7 | 1.65 | 2.1 | 2.5 | 2.8 | - | - | - | - | 2.0/3.0/3.2 |

| - | - | 26.4* | - | - | - | - | - | - | - | - | 2.0/2.5 |

| 20 | 3/4 | 27.2 | 1.65 | 2.1 | 2.5 | 2.9 | - | - | - | - | 2.0/2.8/3.0/3.2 |

| - | - | 33.4* | - | - | - | - | - | - | - | - | 2.0/2.5/3.0 |

| 25 | 1 | 34.0 | 1.65 | 2.8 | 3.0 | 3.4 | - | - | - | - | 2.0/2.5/3.5/4.0 |

| 32 | 1 1/4 | 42.7 | 1.65 | 2.8 | 3.0 | 3.6 | - | - | - | - | 2.0/2.5/3.5/4.0/4.5/5.0 |

| 40 | 1 1/2 | 48.6 | 1.65 | 2.8 | 3.0 | 3.7 | - | - | - | - | 1.5/2.0/2.5/3.5/4.0/4.5/5.0 |

| 50 | 2 | 60.5 | 1.65 | 2.8 | 3.5 | 3.9 | - | - | - | - | 2.0/2.5/3.0/4.0/4.5/5.0 |

| 65 | 2 1/2 | 76.3 | 2.1 | 3.0 | 3.5 | 5.2 | - | - | - | - | 2.0/2.5/4.0/5.0/5.5 |

| 80 | 3 | 89.1 | 2.1 | 3.0 | 4.0 | 5.5 | - | - | - | - | 2.0/2.5/3.5/4.5/5.0/6.0 |

| 90 | 3 1/2 | 101.6 | 2.1 | 3.0 | 4.0 | 5.7 | - | - | - | - | 2.0/2.5/3.5/5.0/6.0 |

| 100 | 4 | 114.3 | 2.1 | 3.0 | 4.0 | 6.0 | - | - | - | - | 2.0/2.5/3.5/4.5/5.0/6.5 |

| 125 | 5 | 139.8 | 2.8 | 3.4 | 5.0 | 6.6 | - | - | - | - | 2.5/3.0/3.5/4.0/5.5/6.0/6.5 |

| 150 | 6 | 165.2 | 2.8 | 3.4 | 5.0 | 7.1 | 2.8 | 3.4 | 5.0 | 7.1 | 3.0/3.5/4.0/5.5/6.0/6.5/7.0 |

| 200 | 8 | 216.3 | 2.8 | 4.0 | 6.5 | 8.2 | 2.8 | 4.0 | 6.5 | 8.2 | 3.0/3.5/4.5/5.0/6.0/7.0 |

| 250 | 10 | 267.4 | 3.4 | 4.0 | 6.5 | 9.3 | 3.4 | 4.0 | 6.5 | 9.3 | 3.0/3.5/4.5/6.0/7.0 |

| 300 | 12 | 318.5 | 4.0 | 4.5 | 6.5 | 10.3 | 4.0 | 4.5 | 6.5 | 10.3 | 3.0/3.5/5.0/6.0/7.0 |

| 350 | 14 | 355.6 | - | - | - | 11.1 | 4.0 | 5.0 | 8.0 | 11.1 | 6.0 |

| 400 | 16 | 406.4 | - | - | - | 12.7 | 4.5 | 5.0 | 8.0 | 12.7 | 4.0/6.0 |

| 450 | 18 | 457.2 | - | - | - | 14.3 | 4.5 | 5.0 | 8.0 | 14.3 | - |

| 500 | 20 | 508.0 | - | - | - | 15.1 | 5.0 | 5.5 | 9.5 | 15.1 | - |

| 550 | 22 | 558.8 | - | - | - | 15.9 | 5.0 | 5.5 | 9.5 | 15.9 | - |

| 600 | 24 | 609.6 | - | - | - | 17.5 | 5.5 | 6.5 | 9.5 | 17.5 | - |

| 650 | 26 | 660.4 | - | - | - | 18.9 | 5.5 | 8.0 | 12.7 | - | - |

| 700 | 28 | 711.2 | - | - | - | - | 5.5 | 8.0 | 12.7 | - | - |

| 750 | 30 | 762.0 | - | - | - | - | 6.5 | 8.0 | 12.7 | - | - |

| 800 | 32 | 812.8 | - | - | - | - | - | 8.0 | 12.7 | - | - |

| 850 | 34 | 863.6 | - | - | - | - | - | 8.0 | 12.7 | - | - |

| 900 | 36 | 914.4 | - | - | - | - | - | 8.0 | 12.7 | - | - |

| 1000 | 40 | 1016.0 | - | - | - | - | - | 9.5 | 14.3 | - | - |

| Remark |

(1)Other nominal diameter and wall thickness subject to the approval of vendor and purchaser with MOQ requirement. (2)Materials according to ASTM A240. |

||||||||||

|

Standard & Grade |

Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | Mo | ||

|

CNS 6331 |

304TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~11.0 | 18.0~20.0 | |

| 304L1TP | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~13.0 | 18.0~20.0 | ||

| 304L2TP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 9.0~13.0 | 18.0~20.0 | ||

| 316TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| 316L1TP | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| 316L2TP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 12.0~16.0 | 16.0~18.0 | 2.0~3.0 | |

|

ASTM A213 A312 |

TP304 | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~11.0 | 18.0~20.0 | |

| TP304L | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~13.0A | 18.0~20.0 | ||

| TP316 | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| TP316L | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

|

JIS G3459 |

SUS304TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~11.0 | 18.0~20.0 | |

| SUS304LTP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 9.0~13.0 | 18.0~20.0 | ||

| SUS316TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| SUS316LTP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 12.0~16.0 | 16.0~18.0 | 2.0~3.0 | |

|

Remark |

A ASTM A213 grade TP304L shall have an Ni content of not less than 8.00% and not more than 12.00%. |

||||||||

| Item | ||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard | Outside Diameter | Thickness | Length | |||||||||||||||||||||||||||||||||||

| ASTM A312 |

|

Nominal Thickness + 15% -12.5% |

|

|||||||||||||||||||||||||||||||||||

| ASTM A358 |

Based on circumferential measurement ± 0.5% Difference between major and minor outside diameters 1% |

-0.3mm |

|

|||||||||||||||||||||||||||||||||||

|

CNS 6331 JIS G3459 |

O.D. < 30.0mm ± 0.30mm O.D. ≧ 30.0mm ± 1% |

< 2mm ± 0.20mm ≧ 2mm ± 10% |

Definite Cut Lengths |

|||||||||||||||||||||||||||||||||||

|

CNS 13517 JIS G3468 |

O.D. ≦ 318.5mm (300A) ± 1% O.D. > 318.5mm (300A) ± 0.5% |

|

Definite Cut Lengths |

|||||||||||||||||||||||||||||||||||

Stainless Steel Pipes

Stainless Steel Pipes

Stainless Steel Pipes

Stainless Steel Pipes

Stainless Steel Pipes