Introduction of Stainless Steel Welded Pipe

YC INOX is a world-leading supplier of stainless steel welded pipes. We are one of the top 5 stainless steel welded pipe/tube producer worldwide rated by Austria SMI (Steel Market Intelligence) magazine, renowned for excellent product quality, customer serivce, innovation, and social contribution. We provide industry-leading stainless steel pipes according to international standard of ASTM A312/A312M, which refers to straight-seam welded pipe and welded Austenitic stainless steel pipe for general corrosive environment.

YC INOX supplies commercial stainless steel material grades including TP304, TP304L as well as TP316L. These 3 different grades are classified as 300 series in Austenitic stainless steel category. The most common Austenitic stainless steel is TP304/L, which is extensively used across different industries. As for TP316L grade, it has a higher resistance to acid in comparison to TP304/L because it contains an element called molybdenum. This makes TP316L less likely to undergo pitting or crevice corrosion.

YC INOX CO., LTD is a global leading stainless steel pipe & tube manufacturer.

Our professional manufacturing and engineering teams offer products with excellent and consistent quality to our clients all around world.

Our prompt after-sales services can always be relied on by our customers.

Our punctual delivery time makes stock control easy for our customers.

We offer product with tolerance complies with the norm (Specific tolerance requirement is possible. Please contact our sales specialists).

Specific mechanical tests are negotiable between seller and buyer.

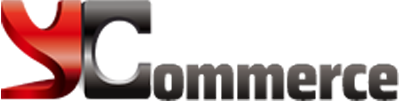

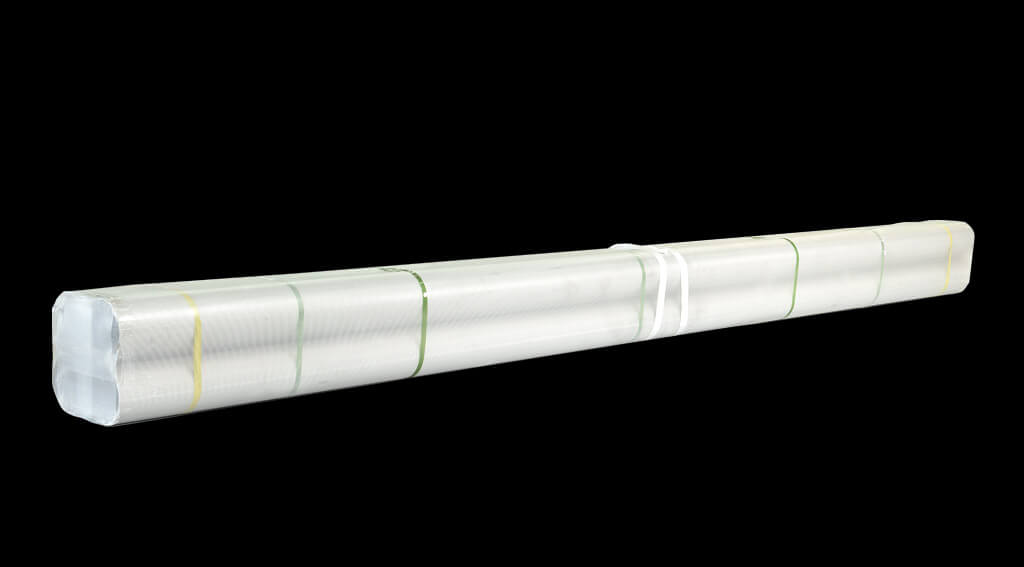

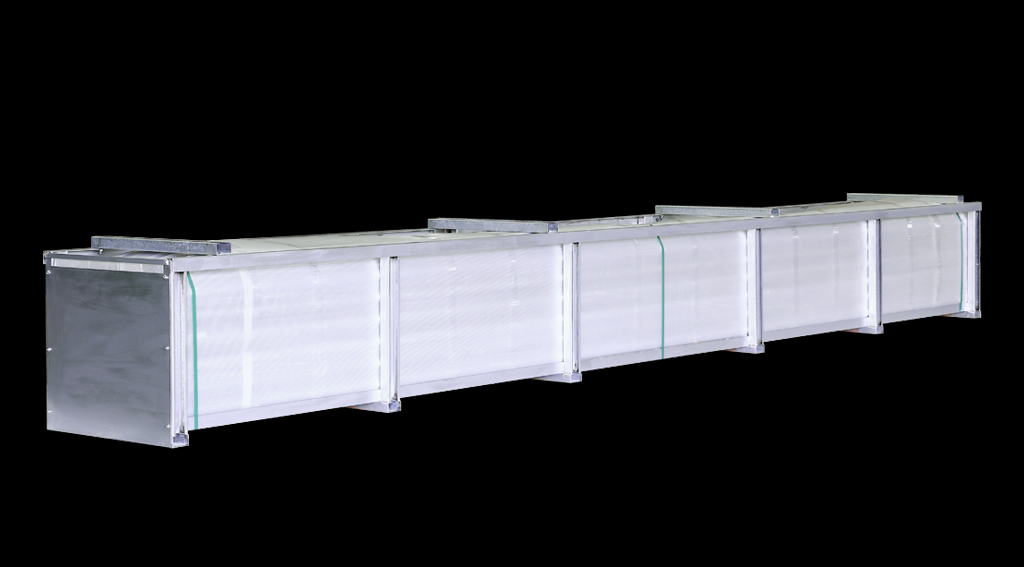

Bundle packing or steel crate packing is available in accordance with clients' preference.

Optional supplementary requirements are negotiatable.

YC INOX, your best choice of stainless steel.

ASTM A312/A312M, A358/A358M, A778/A778M, ASME B36.19M/B36.10M

| 稱呼 | 外徑(mm) | 公稱厚度(mm) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ASME B36.19M | ASME B36.10M | |||||||||

| SCH-5S | SCH-10S | SCH-40S | SCH-80S | SCH-5 | SCH-10 | SCH-20 | STD | XS | ||

| 1/4 | 13.70 | - | 1.65 | 2.24 | 3.02 | - | 1.65 | - | 2.24 | 3.02 |

| 3/8 | 17.10 | - | 1.65 | 2.31 | 3.20 | - | 1.65 | - | 2.31 | 3.20 |

| 1/2 | 21.30 | 1.65 | 2.11 | 2.77 | 3.73 | 1.65 | 2.11 | - | 2.77 | 3.73 |

| 3/4 | 26.70 | 1.65 | 2.11 | 2.87 | 3.91 | 1.65 | 2.11 | - | 2.87 | 3.91 |

| 1 | 33.40 | 1.65 | 2.77 | 3.38 | 4.55 | 1.65 | 2.77 | - | 3.38 | 4.55 |

| 1 1/4 | 42.20 | 1.65 | 2.77 | 3.56 | 4.85 | 1.65 |

2.77 |

- | 3.56 | 4.85 |

| 1 1/2 | 48.30 | 1.65 | 2.77 | 3.68 |

5.08 |

1.65 | 2.77 | - | 3.68 | 5.08 |

| 2 | 60.30 | 1.65 | 2.77 | 3.91 |

5.54 |

1.65 | 2.77 | - | 3.91 | 5.54 |

| 2 1/2 | 73.00 | 2.11 | 3.05 | 5.16 | 7.01 | 2.11 | 3.05 | - | 5.16 | 7.01 |

| 3 | 88.90 | 2.11 | 3.05 | 5.49 | 7.62 | 2.11 | 3.05 | - | 5.49 | 7.62 |

| 3 1/2 | 101.60 | 2.11 | 3.05 | 5.74 | 8.08 | 2.11 | 3.05 | - | 5.74 | 8.08 |

| 4 | 114.30 | 2.11 | 3.05 | 6.02 | 8.56 | 2.11 | 3.05 | - | 6.02 | 8.56 |

| 5 | 141.30 | 2.77 | 3.40 | 6.55 | 9.53 | 2.77 | 3.40 | - | 6.55 | 9.53 |

| 6 | 168.30 | 2.77 | 3.40 | 7.11 | 10.97 | 2.77 | 3.40 | - | 7.11 | 10.97 |

| 8 | 219.10 | 2.77 | 3.76 | 8.18 | 12.70 | 2.77 | 3.76 | 6.35 | 8.18 | 12.70 |

| 10* | 273.10 | 3.40 | 4.19 | 9.27 | 12.70 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 |

| 12* | 323.90 | 3.96 | 4.57 | 9.53 | 12.70 | 3.96 | 4.57 | 6.35 | 9.53 | 12.70 |

| 14 | 355.60 | 3.96 | 4.78 | 9.53 | 12.70 | 3.96 | 6.35 | 7.92 | 9.53 | 12.70 |

| 16 | 406.40 | 4.19 | 4.78 | 9.53 | 12.70 | 4.19 | 6.35 | 7.92 | 9.53 | 12.70 |

| 18 | 457.00 | 4.19 | 4.78 | 9.53 | 12.70 | 4.19 | 6.35 | 7.92 | 9.53 | 12.70 |

| 20 | 508.00 | 4.78 | 5.54 | 9.53 | 12.70 | 4.78 | 6.35 | 9.53 | 9.53 | 12.70 |

| 22 | 559.00 | 4.78 | 5.54 | - | - | 4.78 | 6.35 | 9.53 | 9.53 | 12.70 |

| 24 | 610.00 | 5.54 | 6.35 | 9.53 | 12.70 | 5.54 | 6.35 | 9.53 | 9.53 | 12.70 |

| 26 | 660.00 | - | - | - | - | - | 7.92 | 12.70 | 9.53 | 12.70 |

| 28 | 711.00 | - | - | - | - | - | 7.92 | 12.70 | 9.53 | 12.70 |

| 30 | 762.00 | 6.35 | 7.92 | - | - | 6.35 | 7.92 | 12.70 | 9.53 | 12.70 |

| 32-84 | 813.00-2133.60 | 厚度:6.35~30mm | ||||||||

| 備註 |

(1)顏色標記:可生產能力 (2)其他外徑及厚度需求由買賣雙方協議 (3)*:NPS 10 / OD 273mm ; NPS 12 / OD 323.8mm ( For ASTM A358 / A778 ) |

|||||||||

|

Standard & Grade |

Chemical Composition(%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Ni | Cr | Mo | ||

|

CNS 6331 |

304TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~11.0 | 18.0~20.0 | |

| 304L1TP | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~13.0 | 18.0~20.0 | ||

| 304L2TP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 9.0~13.0 | 18.0~20.0 | ||

| 316TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| 316L1TP | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| 316L2TP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 12.0~16.0 | 16.0~18.0 | 2.0~3.0 | |

|

ASTM A213 A312 |

TP304 | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~11.0 | 18.0~20.0 | |

| TP304L | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~13.0A | 18.0~20.0 | ||

| TP316 | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| TP316L | ≦ 0.035 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

|

JIS G3459 |

SUS304TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 8.0~11.0 | 18.0~20.0 | |

| SUS304LTP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 9.0~13.0 | 18.0~20.0 | ||

| SUS316TP | ≦ 0.080 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 10.0~14.0 | 16.0~18.0 | 2.0~3.0 | |

| SUS316LTP | ≦ 0.030 | ≦ 1.00 | ≦ 2.00 | ≦ 0.045 | ≦ 0.030 | 12.0~16.0 | 16.0~18.0 | 2.0~3.0 | |

|

Remark |

A ASTM A213 grade TP304L shall have an Ni content of not less than 8.00% and not more than 12.00%. |

||||||||

| Item | ||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Standard | Outside Diameter | Thickness | Length | |||||||||||||||||||||||||||||||||||

| ASTM A312 |

|

Nominal Thickness + 15% -12.5% |

|

|||||||||||||||||||||||||||||||||||

| ASTM A358 |

Based on circumferential measurement ± 0.5% Difference between major and minor outside diameters 1% |

-0.3mm |

|

|||||||||||||||||||||||||||||||||||

|

CNS 6331 JIS G3459 |

O.D. < 30.0mm ± 0.30mm O.D. ≧ 30.0mm ± 1% |

< 2mm ± 0.20mm ≧ 2mm ± 10% |

Definite Cut Lengths |

|||||||||||||||||||||||||||||||||||

|

CNS 13517 JIS G3468 |

O.D. ≦ 318.5mm (300A) ± 1% O.D. > 318.5mm (300A) ± 0.5% |

|

Definite Cut Lengths |

|||||||||||||||||||||||||||||||||||

Stainless Steel Pipes

Stainless Steel Pipes

Stainless Steel Pipes

Stainless Steel Pipes

Stainless Steel Pipes