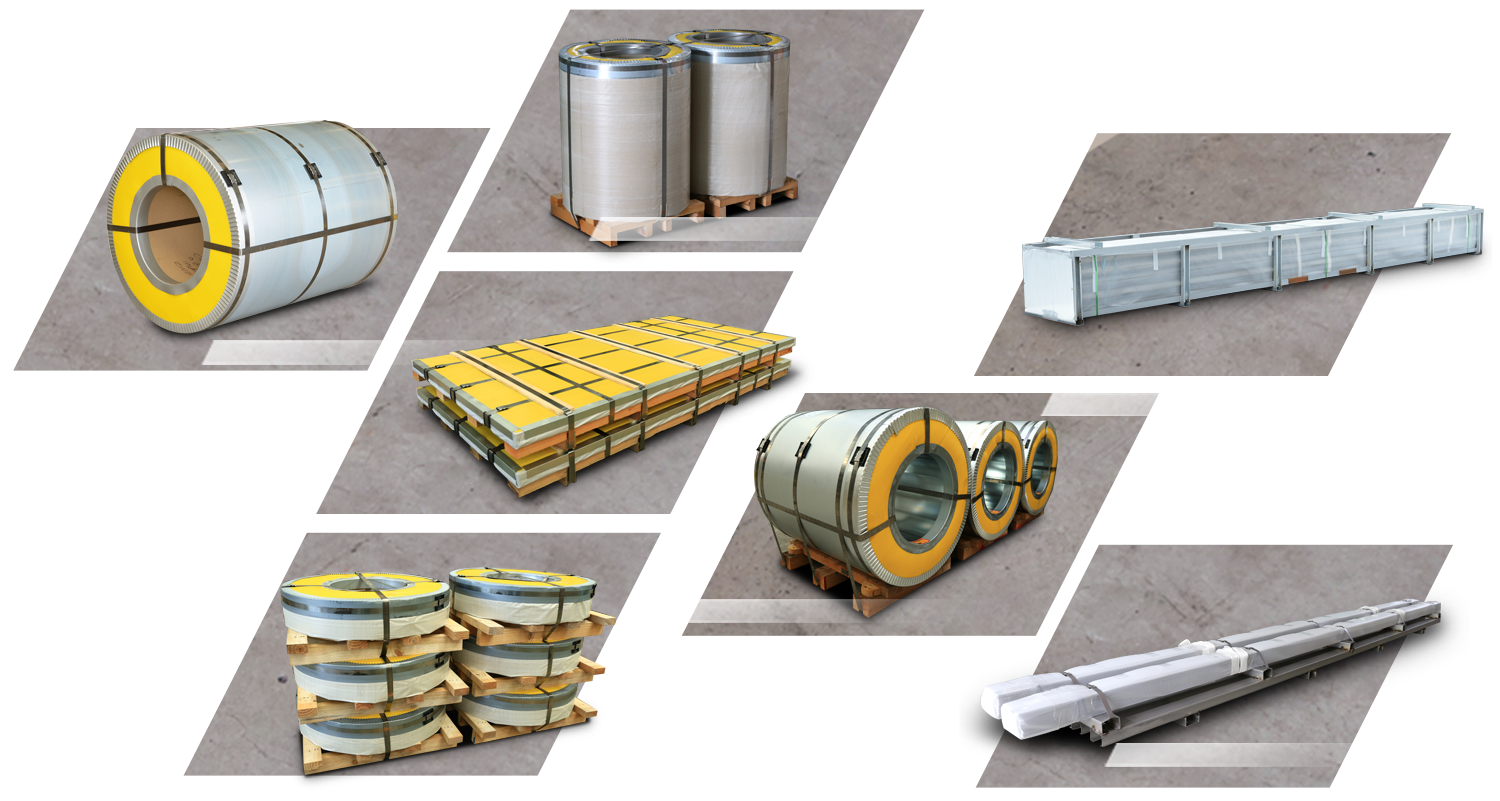

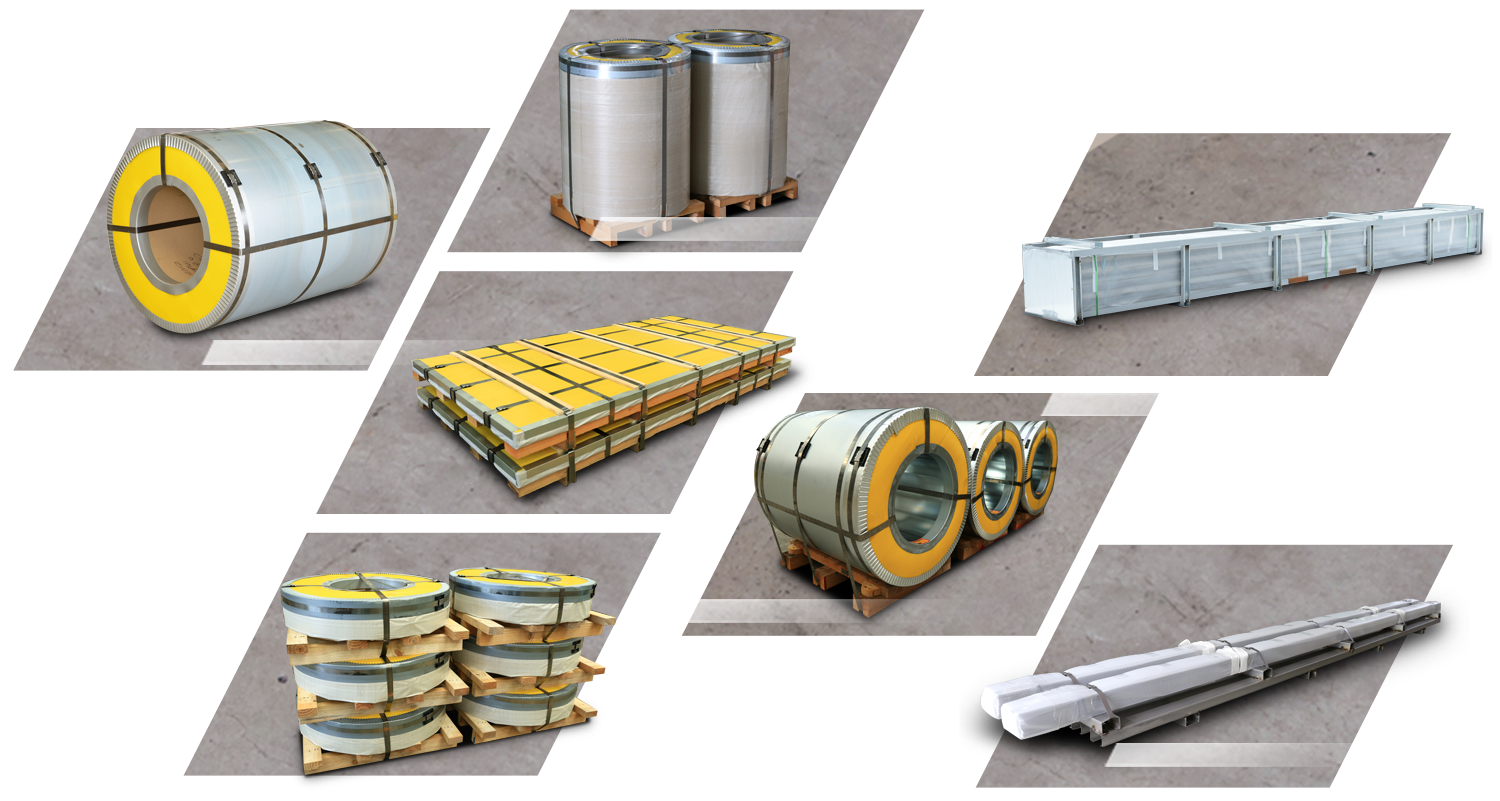

Well–Packed

Through continuous improvement on our products packaging, we now offer several customizable packaging for all of our products. These packaging includes steel crates, steel skids, wooden skids, and PP bundles. Other methods may be available upon requests. We ensure our customers all goods will be properly protected for the transportation.